This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Nanoscale topcoat can turbocharge supported gold nanoparticle catalysts

Researchers from Tokyo Metropolitan University have developed a way to add single nanosheets of mixed metal oxide to gold nanoparticles supported on silica to enhance their catalytic activity.

Converting carbon monoxide to carbon dioxide, they found that the temperature required for the reaction was greatly reduced, with significant improvements over existing methods for coating gold/silica structures. The method paves the way for the development of a wide range of new high-performance catalysts. The findings are published in the journal ACS Applied Materials & Interfaces.

Gold nanoparticles, particles less than five nanometers in diameter, are known to be excellent catalysts for chemical reactions, particularly oxidation reactions like the conversion of harmful carbon monoxide to carbon dioxide. The effect is pronounced when they are mounted on metallic oxides like cobalt oxide, which are more likely to undergo the opposite reaction i.e. reducible oxides.

Unfortunately, not all metallic oxides are reducible. Nanoparticles mounted on irreducible oxides like silica, for example, do not make for an effective catalyst. Given the abundance of silica on our planet, a way to improve the performance of such materials would greatly boost industrial deployment.

This has led scientists to look for ways they can modify supported catalysts to improve their performance.

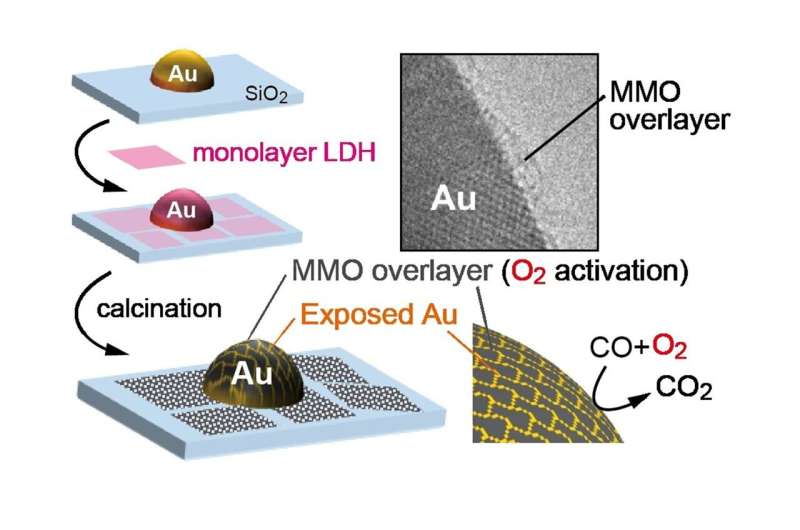

Now, a team led by Associate Professor Tamao Ishida of Tokyo Metropolitan University has come up with a method to deposit single nanosheets of mixed metal oxides (MMOs) using layered double hydroxides (LDHs).

LDHs consist of metal hydroxide nanosheets with some of the metal ions substituted by metal ions with a higher charge, giving the sheet itself a net positive charge; sheets are bound together by negative ions. Importantly, individual nanosheets can be exfoliated and used separately.

In this study, the team coated gold nanoparticles supported on silica, a negatively-charged structure, with positively-charged LDH nanosheets consisting of aluminum and a range of other metals, then exposed them to high temperatures (calcination) to form an MMO nanolayer.

Observing their new catalyst, using transmission electron microscopy, they found that the nanoparticles were coated by a layer of less than one nanometer in thickness. To test their performance, the team used them to convert carbon monoxide to carbon dioxide.

While gold nanoparticles on silica only had a conversion rate of around 20% even at 300° Celsius, their new catalyst showed 50% conversion rate at only 50° Celsius, a reduction of more than 250° Celsius. It was also found to outperform popular "impregnation" methods for MMO coating.

Interestingly, it was found that thicker MMO layers led to worse performance: the high performance comes from having a sub-nanometer coating. Looking at a cobalt aluminum MMO layer in more detail, they found an abundance of oxygen defects in the layer; the team concluded that the close synergy between this defect-filled layer and the gold surface was what gave rise to the enhanced activity.

The new catalyst realized outstanding performance with very low levels of cobalt inclusion, less than 0.3%wt. The findings pave the way for application to a wide range of other materials and a whole family of new, high-performance catalysts.

More information: Kaho Okayama et al, Decoration of Gold and Platinum Nanoparticle Catalysts by 1 nm Thick Metal Oxide Overlayer and Its Effect on the CO Oxidation Activity, ACS Applied Materials & Interfaces (2024). DOI: 10.1021/acsami.3c14935

Journal information: ACS Applied Materials and Interfaces

Provided by Tokyo Metropolitan University