This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Scientists develop maleic acid-treated bacterial cellulose gel for enhancing bone repair

The field of bone tissue engineering (BTE) is a promising avenue for addressing bone injuries and defects by constructing artificial scaffolds with bionic functionalities. Due to its unique 3D network structure, impressive mechanical properties, and excellent biocompatibility, bacterial cellulose (BC) has emerged as a captivating area of research in the realm of scaffold fabrication.

Three-dimensional (3D) printing is a precise technique for constructing intricate structures in damaged tissues or organs, which has been widely applied in the bone tissue engineering field. However, the application of BC for 3D printing faces certain limitations that require attention, such as its dense 3D network structure, which impedes cellular penetration and weakens cell attachment.

In addition, the tightly entangled fibers within BC may pose challenges for its extrusion as a bio-ink during the printing process, which also limit the research that has been conducted on the application of BC in 3D printing.

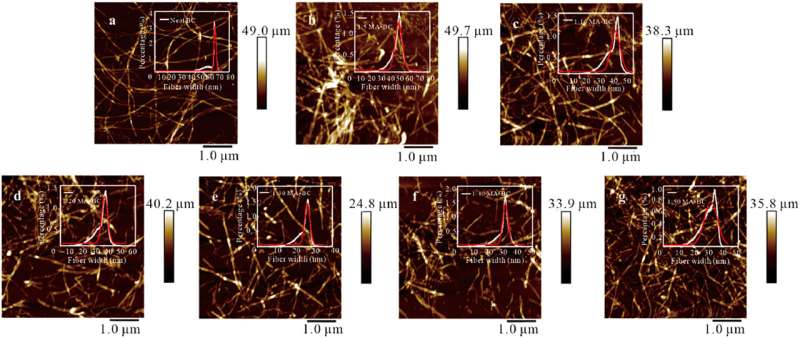

Maleic acid (MA) has emerged as a promising candidate for acid treatment of cellulose, primarily due to its eco-friendly nature and mild reaction conditions. Previous work has proven that MA solution with different concentrations showed various effects on BC physicochemical properties and osteogenesis.

Meanwhile, MA-mediated modification for BC provides reversible reactions, including ester reaction (forward reaction) and ester hydrolysis reaction (backward reaction). Hence, it is necessary to balance the volume of added MA solution in order to ensure the forward reaction for BC modification, which will yield deeper insights into the MA-mediated modification process and unlock the full potential of modified BC in the bone tissue engineering field.

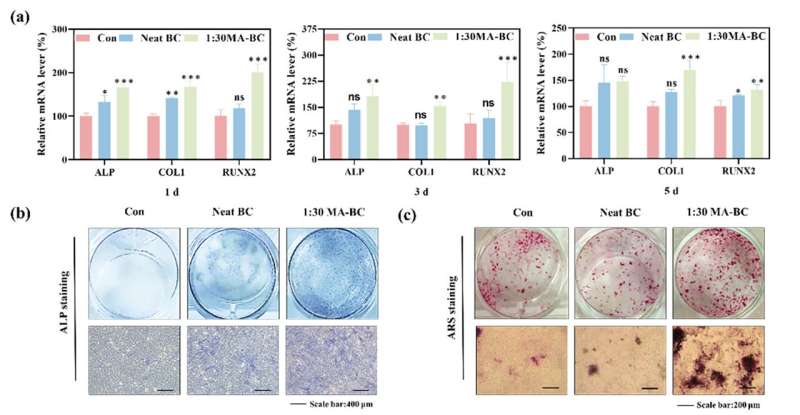

According to Xucai Wang, the investigator who led a recent study published in the Journal of Bioresources and Bioproducts, this provides a new idea for the research of bacterial cellulose in bone tissue engineering. Wang explained, "The esterification process introduced carboxyl groups and hydrophobic properties to BC, thereby enhancing its suitability as a bio-ink for tissue engineering scaffolds. Additionally, the 1꞉30 MA-BC dispersion exhibited excellent biocompatibility, increased osteogenic gene expression, and increased mineralized nodule formation in vitro compared to the neat BC dispersion."

Also, the authors expect this work to provide valuable insights into the potential application of MA-BC dispersions in bone tissue engineering, particularly in facilitating proliferation and differentiation of osteocytes.

More information: Xucai Wang et al, Constructing Osteo-Inductive Bio-Ink for 3D Printing Through Hybridization of Gelatin with Maleic Acid Modified Bacterial Cellulose by Regulating Addition Volumes of Maleic Acid Solution, Journal of Bioresources and Bioproducts (2024). DOI: 10.1016/j.jobab.2024.04.001

Provided by Journal of Bioresources and Bioproducts