This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Thiol-ene click reaction offers a novel approach to fabricate elastic ferroelectrics

A research group led by Prof. Li Runwei and Hu Benlin at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences has developed a facile and efficient approach to fabricate elastic relaxor ferroelectrics via thiol-ene click reaction.

The study is published in the journal Angewandte Chemie International Edition.

Ferroelectrics, which possess switchable spontaneous polarization within a certain temperature range, play a key role in various applications, such as non-volatile memories, sensors, and actuators. With the development of wearable and implantable electronic products, the elastification of ferroelectric materials emerges as a highly promising direction.

The research group has proposed a slight crosslinking method for the intrinsic elastification of ferroelectric materials in Science.

By precisely controlling the crosslinking density, they achieved elasticity while minimizing the effect of structural changes on the material crystallinity, thus pioneering a new interdisciplinary field of elastic ferroelectrics. Subsequently, they conducted extensive research on elastic ferroelectric materials and achieved a number of relevant breakthroughs.

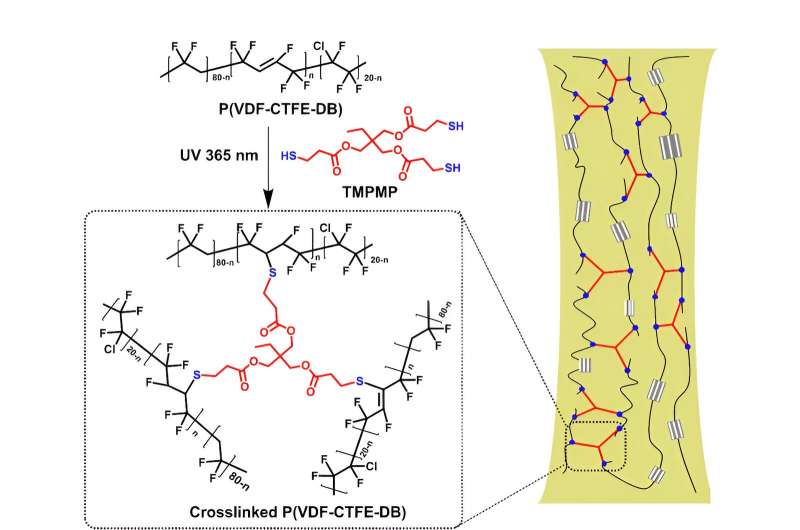

In addition to thermal crosslinking methods for elastic ferroelectrics, the researchers have developed an optical crosslinking method for the elasticization of relaxor ferroelectrics, which exhibit high electromechanical coupling responses and thus have great potential for driving and energy storage applications.

The thiol-ene click reaction was used to achieve the intrinsic elasticization of relaxor ferroelectrics at room temperature by introducing double bonds in poly(vinylidene fluoride-co-chlorotrifluoroethylene) P(VDF-CTFE). The resulting cross-linked film exhibited excellent mechanical resilience, with a fracture elongation of 260%.

Furthermore, the film can maintain 80% strain recovery after 3,000 cycles at a 50% strain, demonstrating superior fatigue resistance thus comparable to commercial fluororubbers. In addition, analysis results verified the relaxor ferroelectric properties of the elastic films.

A fully elastic ferroelectric device with the elastic relaxor ferroelectric film as the dielectric layer was fabricated, which exhibited stable ferroelectric responses under strains up to 70%.

This work provides a new avenue for the exploration and innovation of elastic ferroelectrics for flexible electronics.

More information: Bowen Li et al, Elastic Relaxor Ferroelectric by Thiol‐ene Click Reaction, Angewandte Chemie International Edition (2024). DOI: 10.1002/anie.202400511

Journal information: Angewandte Chemie International Edition , Science

Provided by Chinese Academy of Sciences