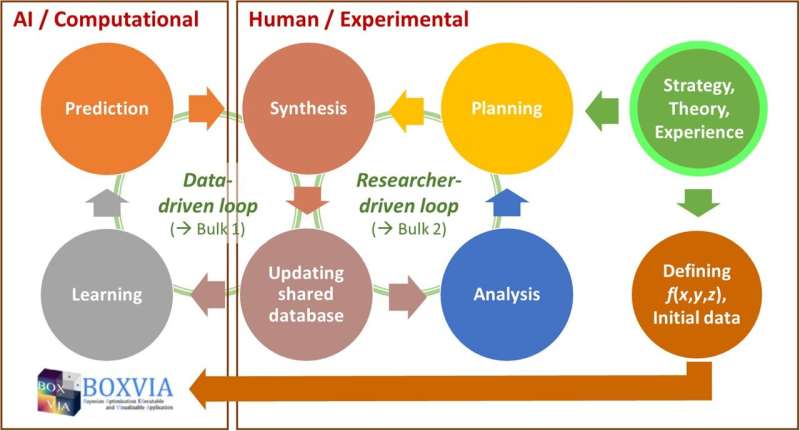

Conceptual schematic of the complementary data- and researcher-driven process designs. Credit: NPG Asia Materials (2024). DOI: 10.1038/s41427-024-00549-5

Scientists have developed the world's strongest iron-based superconducting magnet using AI, in what could be a breakthrough for affordable MRI machines and the future of electrified transport.

Superconducting magnets are capable of producing very strong, stable magnetic fields without the need for large amounts of power. This means they can be used in a range of technologies, including MRI machines that require a strong magnetic field to produce clear 3D images of soft tissue. They can also be used in the next generation of transport, including the SCMaglev train system in Japan.

However, the superconductors currently used are primarily in the form of large coils of superconducting niobium-tin alloy wire. Devices using them need to accommodate this size, which can limit their application.

In a paper, published in NPG Asia Materials, researchers from King's College London and Japan have fabricated a cheap and powerful iron-based superconducting magnet using machine learning (ML), paving the way for widespread and affordable use of the technology.

Dr. Mark Ainslie from the King's Department of Engineering has collaborated on this work with researchers from Tokyo University of Agriculture and Technology, the Japan Science and Technology Agency, the National Institute for Materials Science and Kyushu University.

Dr. Mark Ainslie said, "Superconducting magnets are the backbone of the future. Not only are they used to image cancers with MRI machines, but they will be vital for electric aircraft and nuclear fusion.

"However, the materials and technology required to create traditional copper-based wire superconductors are typically expensive, which has resulted in limited market penetration. Using them in bulk form, as a magnet that doesn't lose its magnetism once magnetized, can result in a smaller footprint in comparison to heavier coils of wire, but copper-based bulk superconductors can take weeks to fabricate.

"Using artificial intelligence (AI), we've produced a cost-effective and scalable alternative using iron, which is a lot easier to work with and opens the door for smaller and lighter weight devices. The first iron-based superconductors were made over 10 years ago, but the magnetic fields they produced were nowhere near strong or stable enough for widespread use.

"While superconducting magnets still need to be cooled to very low temperatures to function effectively, our process lays the groundwork for manufacturers to make them at speed and powerful enough for industrial applications—meaning more MRI machines for cheaper.

"By reducing the need for large amounts of superconducting wire in MRI machines, we can also create a new generation of smaller units that could be deployed at a GP's office, rather than requiring large rooms in hospitals, widening accessibility."

MRI machines have strict requirements for the strength and stability of the magnetic field their magnets produce, to ensure patient safety and image quality. The researchers' prototype is the first iron-based bulk superconductor that meets these requirements.

More information: Akiyasu Yamamoto et al, Superstrength permanent magnets with iron-based superconductors by data- and researcher-driven process design, NPG Asia Materials (2024). DOI: 10.1038/s41427-024-00549-5

Provided by King's College London